White Light Scanning

White light scanning is a 3d-scanning process using a non-contact optical scanning device which uses white light source to project fringes on the part being scanned. The sensor of the scanner which is equipped with two cameras take several images of the part ( with fringes projected on it ) during the measurement and sends these images to a high end PC where an advanced image software calculates point co-ordinates through out the visible area of the part under scan.

Unlike contact scanning, white light scanning picks up the point co-ordinates of the surface being scanned so there is no requirement for probe ball compensation and complexities / errors associated with it.

Services

3D Scanning - Bureau service, providing fast scanning in most cases, with a full range of output formats, including point cloud, section curves and auto surface.

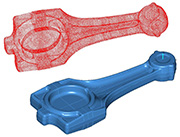

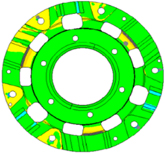

Inspection - CAD models can be compared to scan data to produce 3D colour deformation maps for inspection purposes ideal for moulding and castings with complex forms.

Reverse Engineering - Using 3D point cloud scan data, CAD models can be produced capturing design intent and exporting in a wide variety of formats, including IGES, STEP ,etc . Remodelling and obtaining parametric surfaces

|

|

|

|

Photogrammetric Modelling & Scanning

3D scanning, the process of converting physical objects into precise digital models, enables you to quickly and accurately capture your object's shape and geometries. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection or at any point of a typical manufacturing cycle.

Does Size Matter?

Not for 3D photogrammetry scanning! From cars, boats, aircraft, and buildings mechanical parts, 3D photogrammetry scanning provides you with high quality digital models - no matter how big or small your part is. 3D scanning can help you:

|

Measure parts |

|

Create CAD data |

|

Make parts fit |

|

Rapid prototype |

|

Scale parts up or down |

Reverse Engineering

3D Scan Solutions can help you generate 3D CAD models from existing objects, whether to determine the original design intent, to modernize manufacturing processes, to design a new part to fit to a legacy part, or other. While reverse engineering complex surfaces and intricate architecture, traditional methods like using calipers will fail. 3D Photogrammetry scanning is an invaluable tool in such cases.

|

Obtain CAD data that captures an object's original design intent |

|

Design a new part to fit to a legacy part |

|

Accurately model performance surfaces |

|

Update CAD models of your tooling to match shop-floor |

| changes | |

|

Redesign a part without manufacturing defects |

|

Modernize your manufacturing process |

Quality & Inspection Reporting

3D scanning enables generation of digital data of components & assemblies quickly and in high accuray thereby enabling comprehensive reporting on the quality of as-built parts for first-article and production inspection, and supplier management.

RASCO's quality reporting service provide manufacturers to perform fast, accurate, graphical comparisons between digital reference models and scans of as-built parts for first-article inspection, production inspection and supplier quality management. This service allows manufacturers to rapidly increase product and manufacturing quality, rapidly identify process issues, and build productivity.

Typical Examples of Quality Reporting |

|

| First Produced Sample Quality Check | Supplier Component Quality Check |

|

|

3D Modeling

Create visually stunning 3D models for movie animations, web applications, product advertising and much more, with accurate texture maps and a multitude of output options, including Maya and 3Ds Max. Scan hand models or sketches and translate to incredible 3D models in no time. Some applications include:

|

3D digital models of consumer products for advertising |

|

3D scanning of hand models and mock-ups |

|

Styling surface from scan or sketches |

|

Design from scaled down colored mock-ups |

|

3D character design for movie animations |

|

Panoramic architectural views |

|

360 degree views of consumer products |

|

Exhibit design and visualization |